Best Bulk Packaging 2023 – Top 5 Best Wholesale Packaging Design Ideas

Bulk packaging refers to the large-scale packaging of goods or products in larger quantities for transportation, storage, or distribution purposes. It involves using containers, such as drums, pallets, or large bags, to hold a large amount of the product, typically more than what is intended for direct consumer use. Bulk packaging offers various advantages, including cost savings, efficient handling, and easier logistics, especially for businesses involved in wholesale or industrial distribution. Today, we bring you the top 5 best bulk and wholesale packaging design ideas for 2023.

Best Bulk Packaging 2023 – Top 5 Best Wholesale Packaging Design Ideas

Bulk Packaging Advantages

Bulk packaging plays a significant role in various industries and has several important advantages:

1. Cost savings

Bulk packaging allows for efficient use of resources and reduces packaging material costs. It eliminates the need for individual or smaller packaging units, reducing overall packaging expenses. Moreover, handling and transportation costs are often lower when goods are packaged in bulk.

2. Increased efficiency

Bulk packaging enables more efficient handling and storage of goods. Instead of dealing with numerous individual units, larger quantities of the product can be stored, transported, and handled as a single unit, saving time and labor.

3. Improved logistics

Bulk packaging simplifies the logistics process. With larger quantities of products packaged together, it is easier to load and unload goods, reducing time spent on handling and transportation. This enhances supply chain efficiency and reduces logistical complexities.

4. Reduced environmental impact

Bulk packaging can lead to a reduced environmental footprint. By minimizing the need for additional packaging materials and optimizing transportation efficiency, it can help lower energy consumption, greenhouse gas emissions, and waste generated.

5. Enhanced sustainability

Bulk packaging can support sustainability goals. Using larger containers or packaging materials that are recyclable or reusable can contribute to reducing waste and promoting a more circular economy.

6. Suitable for industrial applications

Bulk packaging is particularly relevant for industrial applications where products are often used in large quantities. It allows manufacturers and distributors to efficiently package and transport goods to industrial customers or other businesses that require bulk quantities.

How To Design Bulk Packaging?

Designing bulk packaging involves several key considerations to ensure optimal functionality and efficiency. Here are some steps to help guide the design process:

1. Understand the product

Begin by thoroughly understanding the product to be packaged. Consider its size, shape, weight, fragility, and any special handling requirements. This information will help determine the appropriate packaging materials and design elements.

2. Choose suitable materials

Select packaging materials that are strong, durable, and suitable for the product and its intended use. Common options include heavy-duty corrugated cardboard, plastic pallets, drums, or flexible bulk bags. Consider factors like strength, moisture resistance, and environmental impact in material selection.

3. Optimize packaging dimensions

Depending on the product and available transportation means, determine the optimal dimensions of the packaging. This involves considering factors like stackability, container utilization, and compatibility with handling equipment. Efficient dimensions can help maximize the number of units that can be transported or stored per shipment, reducing costs.

4. Incorporate protective features

Ensure the packaging design provides adequate protection for the product during handling, storage, and transportation. This may include cushioning materials, corner reinforcements, or dividers to prevent shifting or damage. Consider the specific requirements of the product to mitigate any risks.

5. Consider handling and loading methods

Take into account the handling processes and loading methods used in the supply chain. Design the packaging to be compatible with forklifts, conveyors, or other common handling equipment. Incorporate elements like lifting points or access panels to facilitate easy and safe handling.

6. Labeling and identification

Clearly label the bulk packaging for proper identification and handling. Include important information such as product details, handling instructions, safety warnings, and tracking information. Ensure the labels are durable and legible during the entire transportation and storage process.

7. Sustainability considerations

Explore sustainable packaging options and design choices. Consider using recyclable or biodegradable materials, promoting reusable packaging, or optimizing packaging dimensions to minimize waste and environmental impact.

8. Test and validate

Before implementation, conduct thorough testing and validation to ensure the bulk packaging meets the required performance standards. This may involve subjecting the packaging to stress tests, simulated transportation conditions, or other relevant evaluations.

Top 5 Best Bulk Box Design Ideas 2023

No. 1 Corrugated Bulk Bins

Corrugated bulk bins are strong and durable containers made from heavy-duty corrugated cardboard. They are collapsible for easy storage and transportation and can hold a large volume of products. These bins are commonly used in industries like agriculture, automotive, and retail for shipping and storing bulk items.

No.2 Intermediate Bulk Containers (IBCs)

IBCs are reusable containers made of plastic or metal with a capacity of several hundred to a few thousand liters. They typically have a pallet-like base for easy handling with forklifts or pallet jacks. IBCs are commonly used for liquids, powders, and granular products and are widely utilized in the chemical, food, and pharmaceutical industries.

No.3 Flexitanks

Flexitanks are large, flexible containers made of polyethylene or similar materials. They are used for liquid transportation and can hold up to 20,000 liters of liquid cargo. Flexitanks are commonly used for the bulk transportation of food-grade liquids, chemicals, and other non-hazardous liquids. They offer cost-effective transport solutions compared to traditional shipping methods like drums or tank containers.

No.4 Bulk Bags (FIBC – Flexible Intermediate Bulk Containers)

Bulk bags are large, woven polypropylene bags designed to handle and transport bulk materials such as grains, fertilizers, and construction aggregates. They have lifting loops for easy handling and can hold several hundred to a few thousand kilograms of material. Bulk bags provide a flexible and efficient solution for industries requiring large quantities of dry bulk products.

No. 5 Reusable Plastic Pallets

Plastic pallets are widely used in bulk packaging for their durability, strength, and compatibility with various handling systems. They are made from high-density polyethylene (HDPE) or similar materials and can withstand heavy loads. These pallets are stackable, weather-resistant, and suitable for various industries, including manufacturing, warehousing, and logistics.

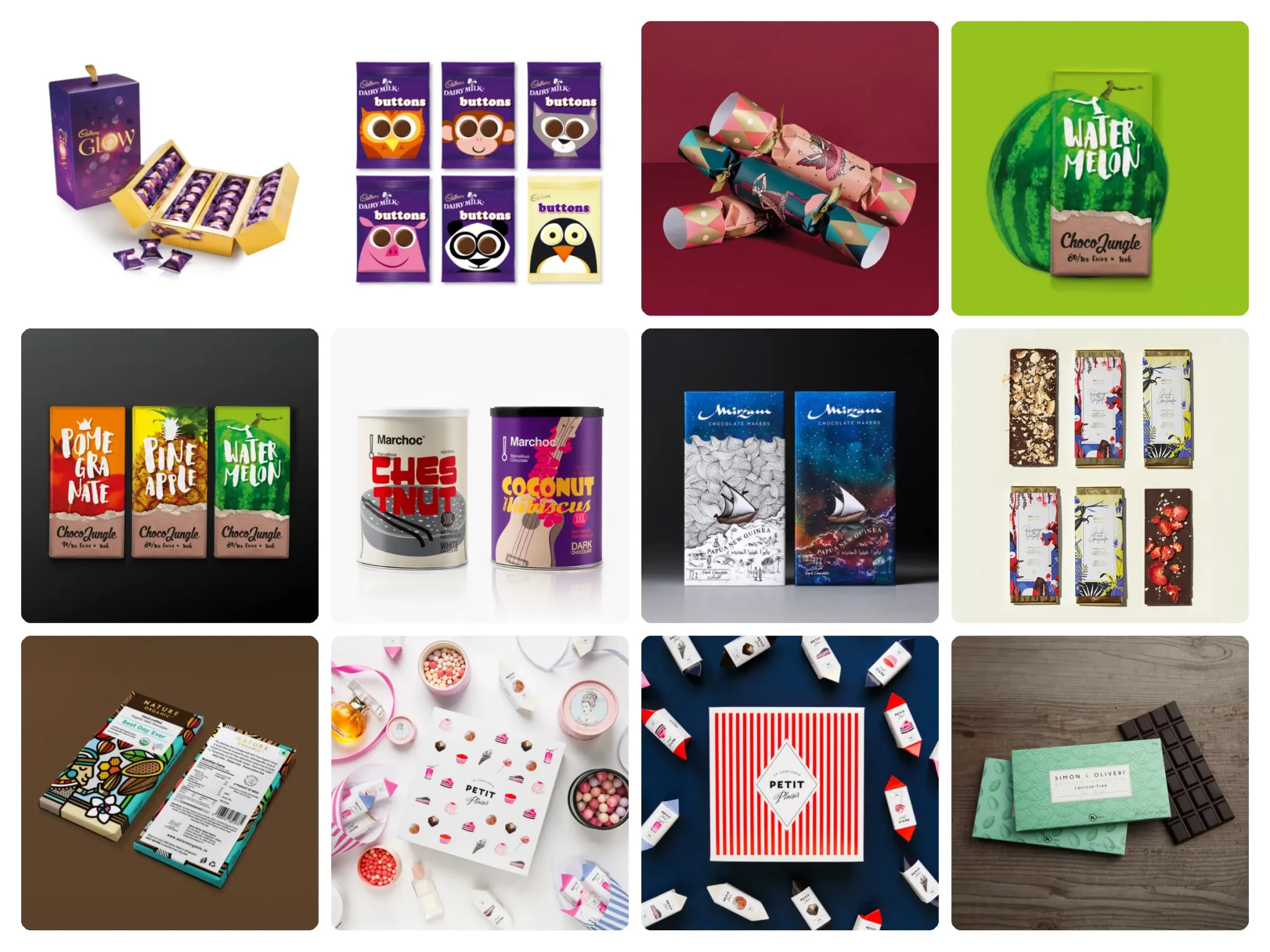

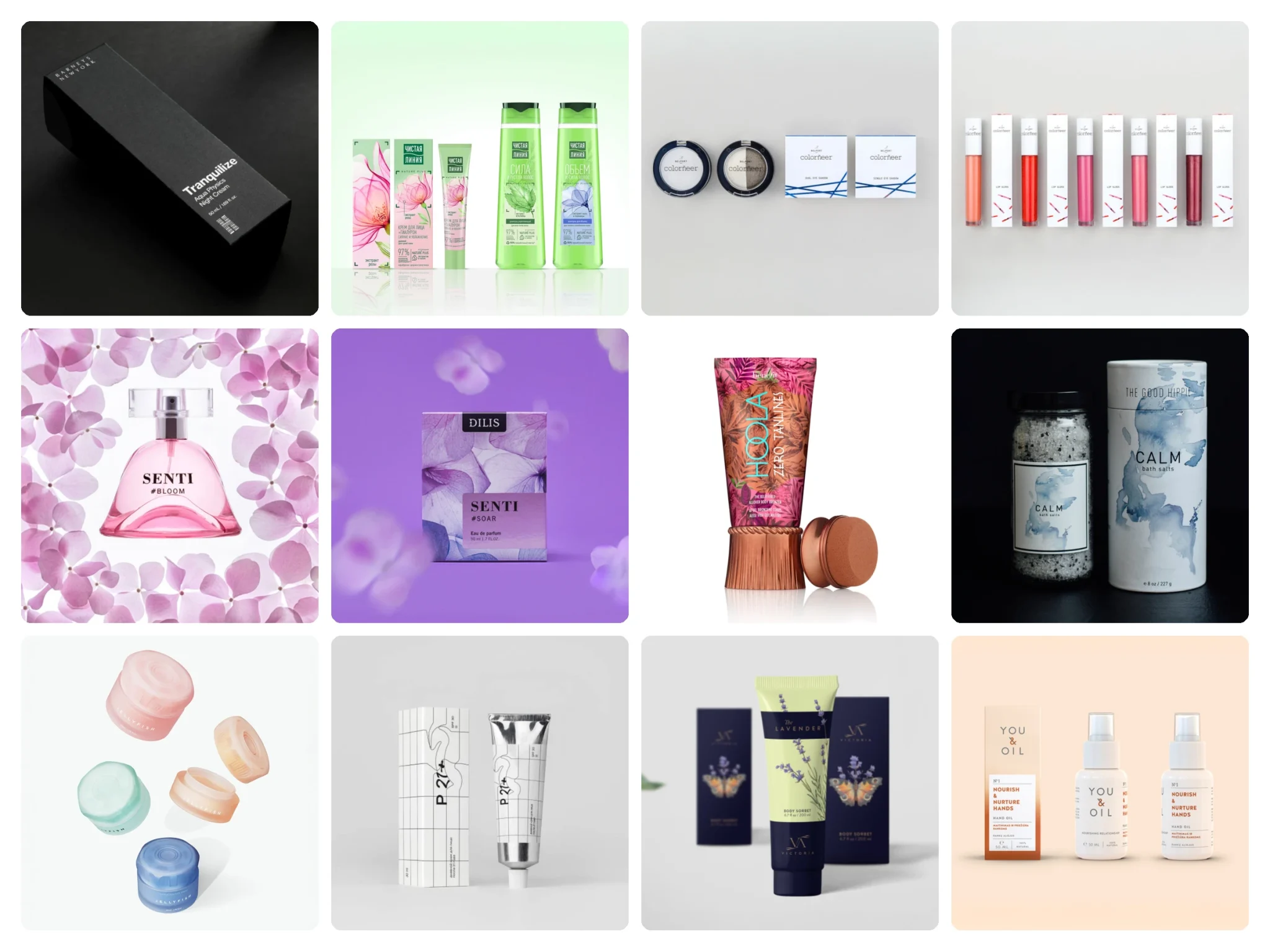

Top 10 Creative Cosmetic Packaging Design Ideas & illustrations 2023 | Luxury-Paper-Box.Com

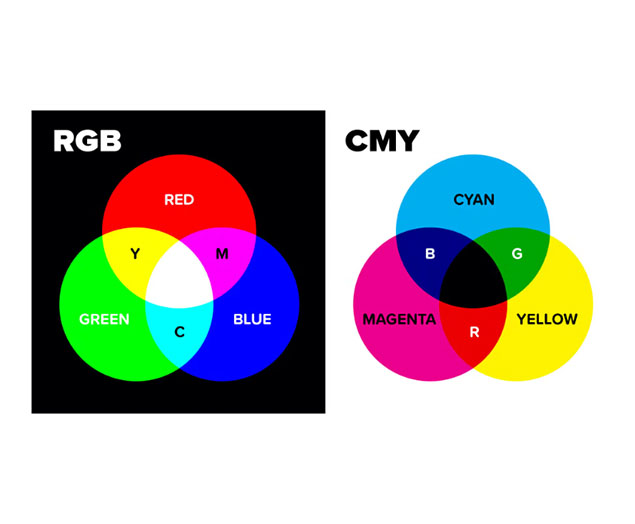

What Is the Difference Between RGB and CMYK

kali@luxury-paper-box.com

kali@luxury-paper-box.com