Cardboard Box Guide: Types, Advantages & Design Tips

Cardboard packaging refers to the use of cardboard materials for packaging various products. It is a widely used and versatile packaging solution due to its strength, affordability, and recyclability. Cardboard packaging can take various forms, including boxes, cartons, trays, inserts, and displays. Read our cardboard box packaging guide, we talk about the types, advantages, and how to design.

Cardboard Box Guide: Types, Advantages & Design Tips

Cardboard boxes, in particular, are commonly used for shipping and storage purposes. They are available in different shapes and sizes to accommodate a wide range of products. Cardboard packaging can be customized with printing, branding, and design elements to enhance product visibility and create a cohesive brand image. The corrugated fiberboard used in cardboard packaging provides protection and cushioning for the packaged items, safeguarding them from damage during handling and transportation. Additionally, cardboard is lightweight, making it cost-effective for shipping while also reducing overall environmental impact compared to heavier packaging materials.

Cardboard Packaging Types

There are several types of cardboard packaging commonly used in the industry. Here are some examples:

1.Cardboard Boxes: These are the most common type of cardboard packaging. They come in various shapes and sizes, such as regular slotted containers (RSC), tuck-top boxes, hinged boxes, and more. Cardboard boxes are used for shipping, storage, retail display, and product packaging.

2. Corrugated Boxes: Corrugated cardboard consists of fluted layers sandwiched between two flat linerboard layers. Boxes made from corrugated cardboard offer enhanced strength and cushioning properties, making them ideal for protecting fragile or heavy items during transportation.

3. Folding Cartons: Folding cartons, also known as paperboard cartons, are lightweight and usually made from solid bleached sulfate (SBS) or recycled paperboard. They are commonly used for packaging consumer goods like cosmetics, pharmaceuticals, food products, and retail items. Folding cartons can be easily folded and assembled into various shapes.

4. Tubes and Cores: Cardboard tubes and cores are cylindrical structures made from cardboard and are used for packaging rolled products like posters, rolls of fabric, or large-format prints. They provide protection and stability while facilitating easy handling and transportation.

5. Cardboard Pallets: Cardboard pallets offer an alternative to traditional wooden or plastic pallets. They are made from corrugated cardboard and are lightweight yet sturdy. Cardboard pallets are used for transporting and storing goods, providing a cost-effective and recyclable solution.

6. Point-of-Purchase (POP) Displays: POP displays are temporary displays made from cardboard that are placed near the point of sale to promote and showcase products. They are often used in retail environments to capture consumer attention and drive sales.

7. Inserts and Dividers: Cardboard inserts and dividers are used to separate and protect individual items within a package. They provide additional support and cushioning, ensuring the products remain secure and undamaged during transit.

How To Design Your Cardboard Packaging?

Designing cardboard packaging involves a combination of creativity, functionality, and practicality. Here are some steps to guide you in the process:

1. Understand the Product: Begin by thoroughly understanding the product that will be packaged. Consider its shape, size, weight, fragility, and any specific requirements for protection or storage.

2. Determine Packaging Objectives: Clearly define your packaging objectives. Consider factors such as brand representation, product visibility, ease of use, sustainability, and cost-effectiveness. This will help guide your design decisions.

3. Sketch and Conceptualize: Start with rough sketches of your packaging design ideas. Consider the overall structure, shape, opening mechanism, and any specific features required to meet the product’s needs. Explore different options and iterate on your concepts.

3. Consider Structural Integrity: Ensure that your design provides sufficient structural integrity to protect the product during shipping and handling. Consider using corrugated cardboard or incorporating support structures like inserts or dividers to prevent damage.

4. Incorporate Branding and Graphics: Your packaging design presents an opportunity to showcase your brand and communicate important information. Incorporate your brand colors, logo, visuals, and any necessary product details or marketing messages. Consider the overall aesthetic appeal and ensure it aligns with your brand identity.

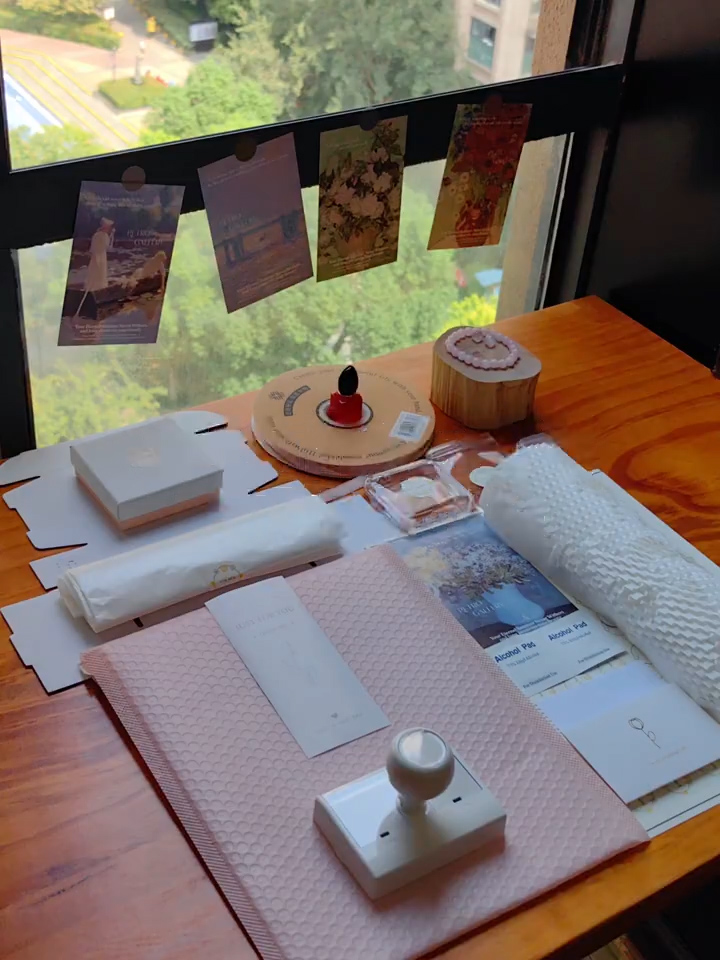

5. Create Mockups: Once you have a refined design concept, create physical or digital mockups of the packaging to evaluate its appearance, functionality, and ergonomics. Mockups help assess how well the packaging fits the product and identify any potential issues or improvements.

6. Test and Iterate: Conduct practical tests to ensure the packaging design meets its intended purpose. Test its durability, ease of assembly, and overall user experience. Gather feedback and make iterative improvements as necessary.

7. Implement Sustainable Practices: Consider sustainability in your cardboard packaging design. Opt for recyclable or compostable materials, minimize the use of non-recyclable components, and prioritize efficient material usage to reduce waste.

8. Seek Expert Input: If needed, consult with packaging experts or printing companies with experience in cardboard packaging design. They can provide valuable insights, recommendations, and assistance in optimizing your design.

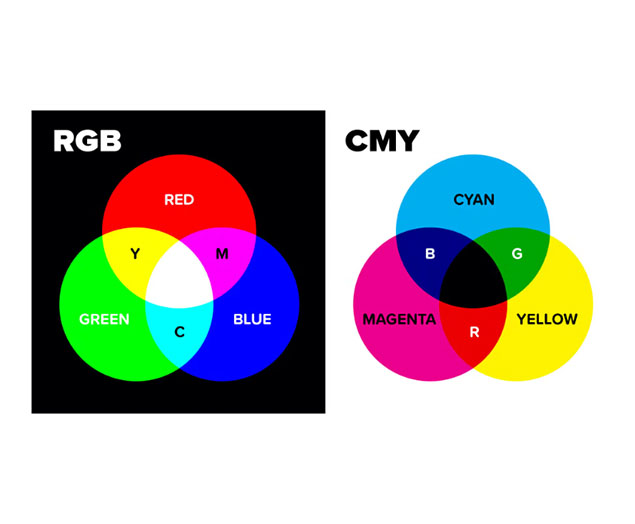

9. Finalize and Prepare for Production: Once you are satisfied with the design, finalize the artwork and specifications, including die lines, color profiles, and any special finishing requirements. Coordinate with printers or packaging manufacturers to ensure a smooth transition from design to production.

Top 10 Creative Cosmetic Packaging Design Ideas & illustrations 2023 | Luxury-Paper-Box.Com

Perfume Packaging Design Trends 2025

Best Chocolate Packaging Designs of 2025

How E-commerce Packaging Wins Hearts (and Wallets)

kali@luxury-paper-box.com

kali@luxury-paper-box.com