How To Choose & Design Carton Sealing Tape

Now many enterprises lack professional knowledge of packaging tape, so it is easy to be led into a misunderstanding when purchasing tape, and because of their own imagination, it is easy to create a source of jerry-building. Therefore, enterprises should pay attention to the following aspects when purchasing packaging tape. First, let’s talk about the calculation method when selecting the tape. Many companies do not know how to choose indicators when buying tapes, and many businesses are also confused (some of them just know the purchase price). Now, the types of tapes are glue thickness, diameter, meters, and yards. The most standard is to use meters or yards. Among them, the places used by unscrupulous businessmen are all-inclusive.

Glue thickness

In order to increase the thickness of the whole roll of tape, small manufacturers are willing to add impurities. For the thickness of the tape calculated in microns, even the smallest impurities will increase the thickness of the tape by a generation. This is why we see many yellow and green tapes in the market.

Diameter

The most direct way is to increase the thickness of the paper tube. Many low-quality adhesive tapes have even made the thickness of the paper tube 10 mm. Below is a set of calculation data and pictures to see how much profit there is.

Yards

This is the most ridiculous count. It is often seen that some tape sellers say they have 1000 yards, 800 yards, and even 1500 yards. They only know that they call the number of laps the number of yards, which is ridiculous. First, I understand that 1 yard=0.9144 meter.

How to select tape for sealing carton

Smell

If the taste is very strong and there is a sour smell, the retention of this tape is very poor. Especially in the low-temperature environment, the tape will basically crack when it is stuck to the carton. The stronger the taste is, the more sticky the initial adhesion is. But soon the adhesive surface will be dry and lose its adhesive property, which is shown by cracks on the surface of the tape. Because of uneven glue application.

See the brightness of the film

Generally, low-quality adhesive tape is dark, which has a very high probability of breaking and poor strength.

The thickness of the hand-felt film

The adhesive tape with hard felt film is generally inferior, and the actual number of meters will decrease due to the film thickness. The film used for good tape is relatively soft and has good elongation when stretched by hand.

Look at the color

Generally, the whiter the appearance of the transparent tape, the fewer impurities in the tape, to ensure normal adhesion. The tape below 100 meters has a certain degree of transparency to see the paper tube. The yellow tape is used to check whether there are irregular white spots on the surface of the tape. What cannot be removed by hand is the mark of impurities or glue dry. This product usually has a smell.

Paper tube

The tape used for thick paper tubes is generally used to mislead consumers. The inner diameter of the paper tube of the adhesive tape is 7.6 cm, but the thickness of the paper tube has been paid enough attention to by low-quality adhesive tape, which has something to do with many consumers. Many people think that the thicker the paper tube is, the larger the outer ring is, and the more the adhesive tape will roll. It seems very correct at a glance, but can you calculate it carefully? Let’s say we use a 3 mm paper tube to compare it with a 7 mm paper tube. If the thickness of the pure tape from the outer diameter of the paper tube to the edge of the tape is 1 cm for two rolls of tape, we can use the mathematical formula to calculate how many meters more tape can be used for each 1 cm of adhesive thickness between a 7 mm paper tube and a 3 mm paper tube?

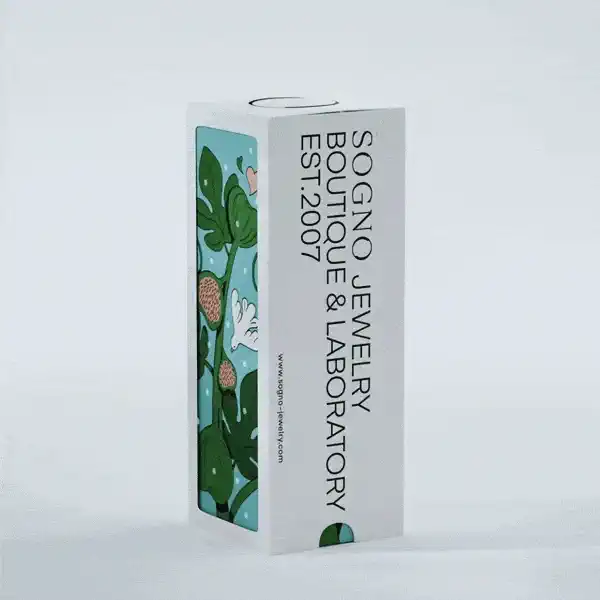

Characteristics of printing sealing glue

When an enterprise develops to a certain extent, it must establish its own corporate image. If the products produced by its own factory want to get rid of the traditional image, upgrade and further position, the external packaging is undoubtedly the first thing to improve. Customizing the printing sealant for its own factory has the following benefits.

-Improve the brand image of the factory.

-It can be used for product promotion, and can also print the business contact information, address, telephone number, etc. of the enterprise.

-Printing the custom carton box sealing glue can play a role in anti-theft. Previously, some customers told us that the logistics company always had less or no goods in the box, and even pointed out that defective goods were coming in. If this is the case, printing the box sealing glue can play a role in anti-theft sealing.

-The printing box sealing glue can drive the sales of your products. The well done printing box sealing glue has a generous and beautiful appearance, which attracts customers’ attention and has a preconceived effect on your products.

Top 10 Creative Cosmetic Packaging Design Ideas & illustrations 2023 | Luxury-Paper-Box.Com

10 Customs Of The Spring Festival (Lunar New Year) You Need To Know

Top 10 Best Lattafa Perfumes for Women & Men in 2024

Top 10 Best Packaging Design Software 2023 (Free & Paid)

Best Chocolate Packaging Designs of 2025

Natural Concept Perfume Design Ideas: Tell Your Brand Story

kali@luxury-paper-box.com

kali@luxury-paper-box.com