How Was A Beautiful Packaging Box Born? – Gift Box Design Process

With the steady development of gift box packaging technology and the continuous updates of printing and packaging technology, the production process of packaging box printing has been greatly simplified. Now Luxurypaperbox.com tells you the specific process:

8 Design Process of Gift Box

1. Design

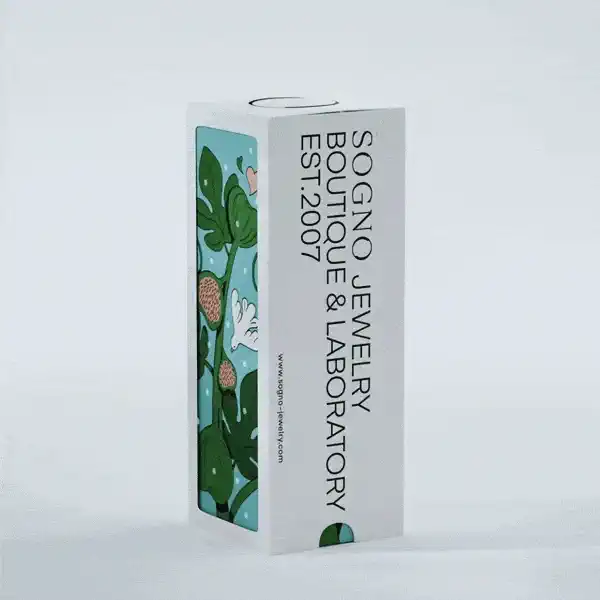

Many packaging box designs are designed by enterprises or customers themselves or by design companies, because design is the first step, what kind of pattern or size, structure, color, etc. you want. Of course, the packaging box printing factory also provides services to help customers design.

2. Sampling

When customizing printing packaging boxes for the first time, digital samples are usually required, and more strictly, it may even be necessary to use a printing machine to make a solid sample. This is because when making a digital sample again, there may be differences in color with the digital sample during mass printing, and printing machine to make a solid sample can ensure consistency in color during mass production.

3. Publishing

After the sample is confirmed, normal mass production can be carried out. For the production and production of packaging and printing factories, this is actually the first step. The color process of the current color box packaging box is very beautiful, so the published version colors are also diverse. Many color box packaging boxes not only have four basic colors, but also spot colors, such as special red, special blue, black, etc. These are all spot colors, which are different from the normal four colors. A few colors make up several PS printing plates, and spot colors make up a unique one.

4. Paper material

The selection of materials for the color box packaging box has been determined during the sampling process. Here is the type of paper used for the printing and production of the packaging box

-Single copper paper, also known as white cardboard, is suitable for color box packaging boxes. Single box printing is commonly used, with a general weight of 250-400 grams.

-Coated paper uses Coated paper as the packaging box, which is generally used as the face paper, that is, Coated paper prints the pattern and then mounts it on the gray board paper or wooden box, which is generally suitable for the packaging of hardcover boxes.

-Whiteboard paper is a type of paper with one side white and one side gray, with a white side printed pattern. It can be used as a single box or as a mounting pit paper box. We will not explain paper more here.

5. Printing

The printing process requirements of color box packaging boxes are very high, and Color difference, ink dot, needle position overprint, scratch and other problems are the most taboo, which will also bring trouble to post press processing.

6. Printing surface treatment

Surface treatment, common methods for color box packaging are over gloss glue, over matte glue, UV, over gloss oil, over matte oil, and gilding.

7. Die-cutting forming

Die cutting and forming is an important and final step in the post press processing. If not done well, the previous efforts will be wasted. Pay attention to the direction of the indentation and avoid exploding lines, and avoid inaccurate die-cutting.

8. Bonding

Many color gift packaging boxes need to be glued together with glue, while some special structure packaging boxes do not need to be glued, such as airplane boxes and sky covers. After bonding, it can be packaged and shipped through quality inspection.

Top 10 Creative Cosmetic Packaging Design Ideas & illustrations 2023 | Luxury-Paper-Box.Com

Best Chocolate Packaging Designs of 2025

Perfume Packaging Design Trends 2025

Gang Run Printing: the Secrets & Advantages in Short Printing

Best Chocolate Packaging Designs of 2025

kali@luxury-paper-box.com

kali@luxury-paper-box.com