Package Filler Types: Choose The Right Filling Material For Your Product Packaging

Whenever we want to make a shipment we must ensure that all our products arrive in perfect condition at their destination. To do this we must choose outer packaging adapted to the dimensions and weight of the product, but it is also equally important to use the right padding material to prevent the products from moving inside the package, and to prevent them from being knocked and broken during shipment.

Advantages of Using Package Filler For Your Product

The packaging filler plays a vital role in protecting our shipments and will provide a better valuation by the customer.

We can therefore say that the use of package filler will provide us with:

Better protection will avoid additional costs:

This is undoubtedly the most important function of packaging filler. If we choose the right material, we will ensure that our shipments reach their addressee without suffering any damage and we will avoid many incidents, return procedures and additional return transport costs.

We will improve our brand image:

The use of filler materials in our shipments will make us improve our customers’ shopping experience. It is essential that this experience is as good as possible so that the customer can make a repeat purchase.

Main Types of Package Filler

There are several types of packaging fillers that will adapt to each type of shipment. Below, we explain them to you:

Filler Material Flakes

Also called filler worms or filler chips, this type of material is very useful in case there are irregular empty spaces inside the boxes. Being a small filling material, it is very easy and quick to fill the entire contents of the box to prevent the products from moving. This type of material is very suitable for the shipment of very fragile and delicate products. It can also be an additional complement to other types of protective materials, such as bubble wrap or foam.

Bubble wrap

Bubble wrap is one of the most commonly used as a filling and protection material. It is mainly used for packing and protecting bulky products such as furniture and paintings, as well as for more fragile products that can easily break (decorative figures, tableware, etc.). An important advantage offered by this type of padding material is its price, since it is an economical, light and very easy to adapt to any type of product as it is totally flexible.

Kraft Paper

It is also very common to use kraft paper or corrugated cardboard as filler material. Its main function is to fill the gaps left inside the shipping packaging and prevent the products from moving during shipment. It is a very environmentally friendly material as it is completely recyclable and biodegradable. In the case of kraft paper, it is mainly used to fill the space of medium or small boxes, such as parapharmacy shipments, small spare parts, etc.

In the case of kraft paper rolls of 31 and 62 cm. we also offer you the option of acquiring the dispenser that will save you time in the preparation of your orders.

Foam

Although the use of foam as a filling material is not the most common, it can also be used as a filling material. Its main use is similar to that of bubble wrap, i.e. as packaging and protection of bulky products with the difference that the foam is softer and its use is recommended for shiny products (e.g. mirrors) and products with polished surfaces.

In cajadecarton.es we have them available in reels and with the option to buy them in 3 different thicknesses (1mm, 2mm and 3mm).

Wooden/grass wire

The market some wood silk, grass silk and other plant fiber filling materials are also used by many businesses, its main selling point is the natural pollution-free, but used businessmen will find that these plant fiber filling materials in the long-distance transport process does not play a good buffering protection, especially when subjected to large external forces, it is easy to appear cargo damage!

Inflatable bags

Inflatable bags belong to the popular inflatable packaging, it is loved by businessmen mainly because it does not have the serious pollution of foam, than plant fiber filling material has a stronger buffer protection ability! Not only that, the inflatable bag is used when the need to inflate, so in the storage of only a thin film, very saving storage space!

Air bubble bags

Air bubble bags must be no stranger to everyone. When we receive the courier, inside by a small bubble wrapped around the plastic bag is the bubble bag. Bubble bag is generally a combination of two layers into a bag, the need to protect the product is put into the package. Bored when we will also be a small bubble squeezed. Air bubble bags are divided into kraft bubble bags, ordinary bubble bags and anti-static bubble bags and so on. Bubble bags have shockproof, moisture-proof, corrosion-resistant and so on, in the transport of small volume of the package when the product with more.

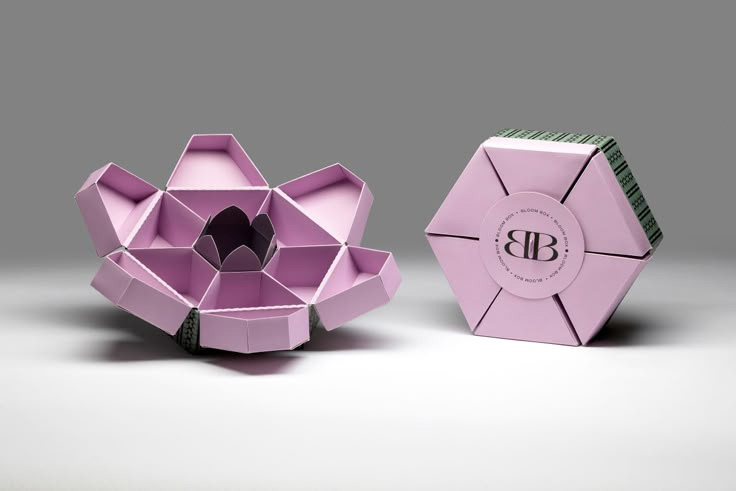

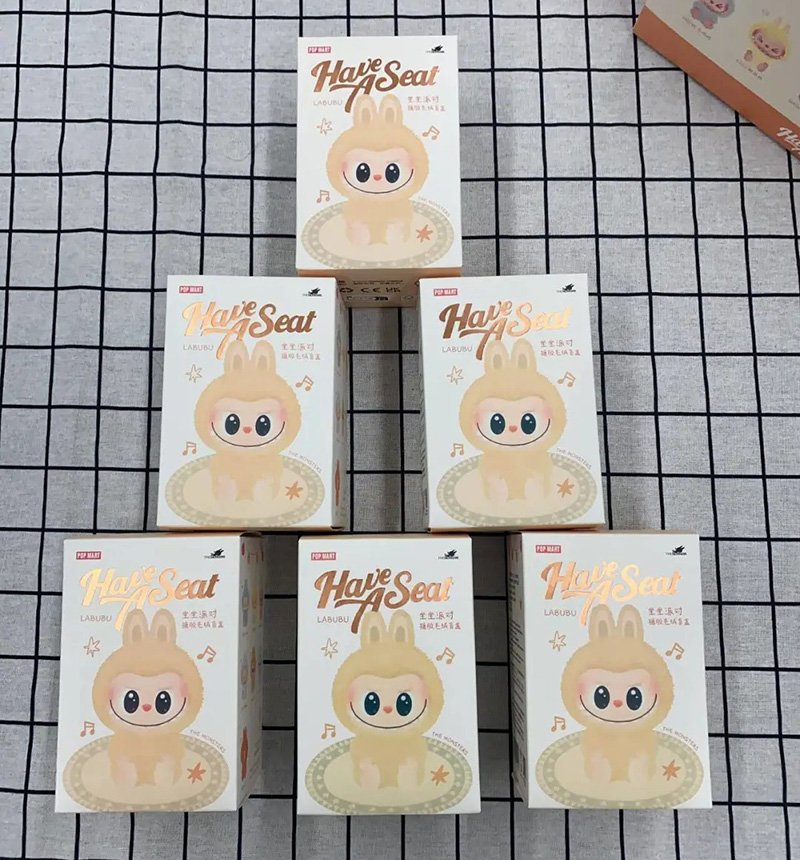

Packaging inserts

Packaging inserts are made from recyclable cardboard and are customized to fit into specific products. Packaging inserts also optimize the appearance of the package and enhance the unpacking experience.

Hopefully, you are now ready to fill your package with the above fillers. Gap padding not only protects the contents of the package; it also impresses your customers before they touch your product.

Top 10 Creative Cosmetic Packaging Design Ideas & illustrations 2023 | Luxury-Paper-Box.Com

10 Customs Of The Spring Festival (Lunar New Year) You Need To Know

Top 10 Best Lattafa Perfumes for Women & Men in 2024

kali@luxury-paper-box.com

kali@luxury-paper-box.com