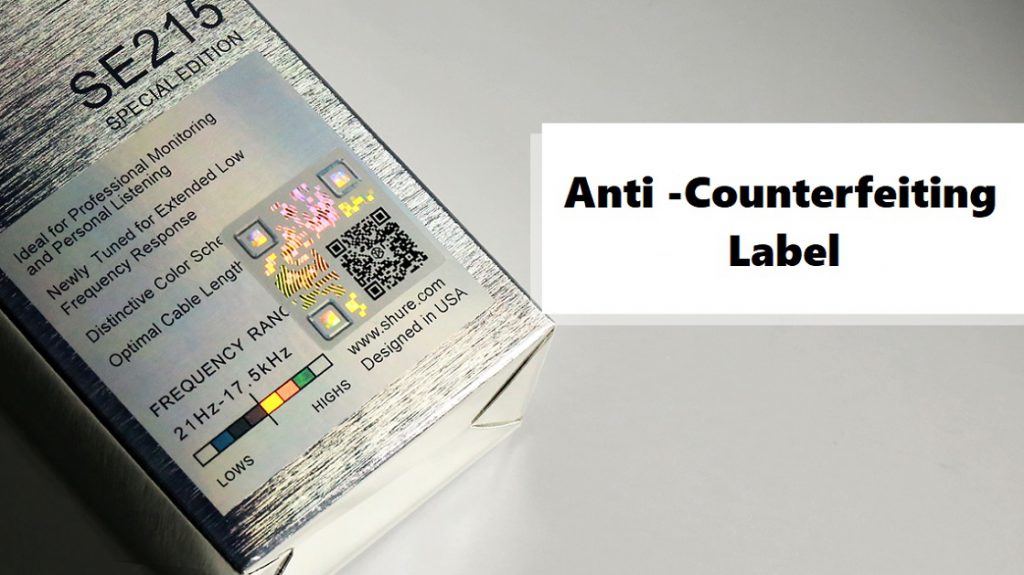

Techniques for Making Anti-Counterfeiting Labels on Electronic Packaging Boxes

In the continuous development of box printing technology, the production of anti-counterfeiting label technology is also constantly improving, in order to make the anti-counterfeiting stronger and not easy to be replicated, most packaging box printing manufacturers will use a variety of anti-counterfeiting technology combinations. Anti-counterfeiting technology often needs to integrate many technologies, such as materials science, optics, chemistry, biology, electromagnetics, imaging and technical science, and other disciplines. Printing security will be based on different needs will take different anti-counterfeiting technology, sometimes using a variety of integrated, sometimes using the above technology in a single one to anti-counterfeiting. In this article, we briefly describe several techniques for making anti-counterfeiting labels on electronic packaging boxes.

- Watermark Paper Anti-Counterfeiting Label

When we make paper, the box logo, pattern, etc. implanted in the paper, using the special distribution of fiber CJE6CKW formed by the pattern, this pattern can only be clearly seen in the face of bright light. Even now that scientific development is rapid, watermark paper is still widely used and considered by anti-counterfeiting experts to be a very effective anti-counterfeiting technology.

- Colored Fiber Paper Anti-Counterfeiting Label

When making paper, add fiber filaments or color dots to the pulp, make paper with an anti-counterfeiting effect, add the fiber of paper is divided into colorless fluorescent fiber and color fiber.

- Metallic Thread Paper Anti-Counterfeiting Label

As the name implies, in the papermaking process, a metal thread or plastic wire is placed in the middle of the paper, as anti-counterfeiting printing paper, this paper also has a clear anti-counterfeiting effect on the anti-counterfeiting. We also according to the different placement of metallic thread in the paper, but also can be divided into open window type, half-open window type, and non-window type three.

The three anti-counterfeiting technologies we mentioned above are anti-counterfeiting labels for paper materials.

- Ink Anti-Counterfeiting Label

Ink anti-counterfeiting label refers to the addition of special performance materials in ink that can play a role in anti-counterfeiting, after a special processing process made of printing ink. Because he is added to the printing ink, so good concealment, low cost, bright colors, simple implementation, easy inspection and reproducibility, and so on. Anti-counterfeiting inks used in box anti-counterfeiting printing mainly include UV fluorescent inks, temperature-changing inks, light-change inks, and magnetic inks.

- Multi-process Combination Anti-counterfeiting Label

A variety of printing equipment and a variety of processes of mutual penetration, such as offset printing, screen printing, concave, soft, hot stamping and spray code, and other process combinations, so that the printed pattern is more abundant. Combined anti-counterfeiting printing technology has raised the threshold for anti-counterfeiting labels to be imitated and counterfeited. Anti-counterfeiting technology to ensure that consumers buy electronic products are regular manufacturers for production, quality assurance, and safety assurance. Protect the rights and interests of consumers and establish a brand image.

Top 10 Creative Cosmetic Packaging Design Ideas & illustrations 2023 | Luxury-Paper-Box.Com

10 Customs Of The Spring Festival (Lunar New Year) You Need To Know

Top 10 Best Lattafa Perfumes for Women & Men in 2024

Top 10 Best Packaging Design Software 2023 (Free & Paid)

Best Chocolate Packaging Designs of 2025

Natural Concept Perfume Design Ideas: Tell Your Brand Story

kali@luxury-paper-box.com

kali@luxury-paper-box.com