The Quality Key To Packaging Color Box Design And Printing

A printed matter can only be carried out according to the three links of prepress, printing, and post-printing. Each process flow is related to the quality of the printed matter. Therefore, the quality management of printed matter must start from prepress to post-printing. The quality management of printed materials can not only rely on work experience, but also rely on intelligent and effective methods. In particular, we should pay attention to digitization, standardization and standardization, and the whole process control of raw materials, production processes, and finished products. At luxurypaperbox.com, we talk about the most important quality key to packaging color box design and printing.

The Quality Key To Packaging Color Box Design And Printing

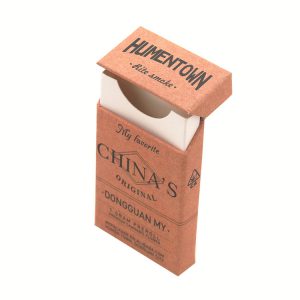

Packaging and printing is a very important part, which reflects the actual effect of the design scheme and printing plate making, and is the key product line of commodities. Post-press production and processing can enhance the added value of printed matter and decorate goods, which is the last stage.

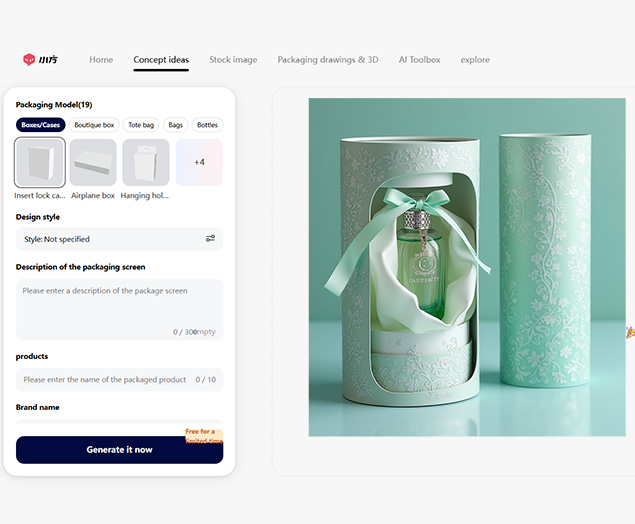

Our packaging customers hope that we can make their products old and new in the custom packaging box, so that customers can have a refreshing feeling, and then achieve the marketing goal. Therefore, the design scheme is a particularly important part of the quality assurance of colorful cartons. It must make the pattern design, color, and text comprehensively reflect the actual effect, highlight the behavior subject, and fully consider the feasibility analysis and expected effect of production and processing after printing plate making and packaging printing.

Use color to reduce the hue or overlapping color as much as possible, except for color samples in special cases. On the text, it is necessary to ensure that the text and pattern design are sorted and integrated properly, and try to prevent the use of too thin and small Yin and Yang font styles. Prevent redundant and complicated pattern design structures, which will make it difficult for packaging and printing.

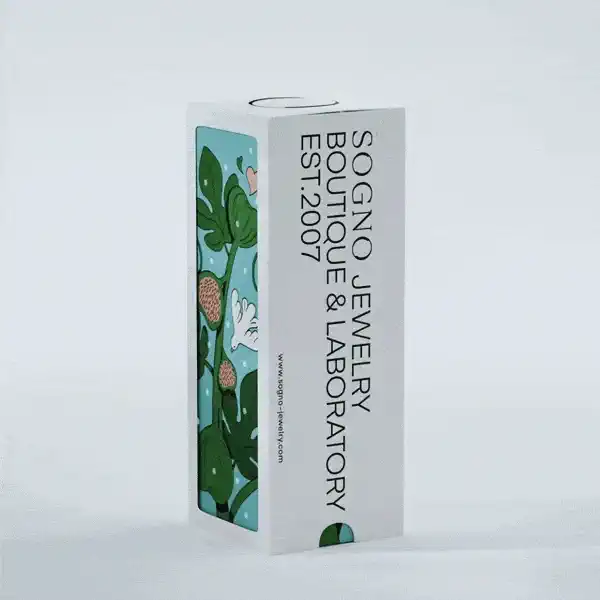

Printing plate making is the middleman of packaging design and decoration and packaging and printing. It is the highway bridge between design scheme and packaging and printing. It has the effect of connecting the past and the future. The daily task of printing and plate making should not only properly reflect the provisions of the paper design scheme, but also correct some parts that do not conform to the printing technical provisions. In the printing and plate-making work, we should first do a good job in the quality approval of the paper manuscript. If the quality of the paper manuscript does not meet the requirements, it is not necessary to be decisive.

When making plates for color-matching printing, the machine and equipment of the printing machine should be fully considered. Whether to make plates by traditional color matching printing or non-colorful color matching printing is more beneficial to packaging printing. In addition, it also has a grasp of the expansion curve of the packaging and printing business outlets of each printing equipment. The quality of each process flow in printing plate making needs to be strictly controlled and data monitoring, such as plate printing and sample fixing.

Prepress includes design scheme, printing, and plate making; Printing includes paper cutting, ink mixing, packaging, and printing; After printing, it includes polishing, polishing, sub film coating, electrochemical aluminum thermal printing, embossing and embossing, mounting, film cutting, and box pasting.

Top 10 Creative Cosmetic Packaging Design Ideas & illustrations 2023 | Luxury-Paper-Box.Com

10 Customs Of The Spring Festival (Lunar New Year) You Need To Know

Top 10 Best Lattafa Perfumes for Women & Men in 2024

Top 10 Best Packaging Design Software 2023 (Free & Paid)

Best Chocolate Packaging Designs of 2025

Natural Concept Perfume Design Ideas: Tell Your Brand Story

kali@luxury-paper-box.com

kali@luxury-paper-box.com