What Are 5 Printing And Bronzing Processing Methods?

Stamping is now an integral element of the printing process, and the technology behind it has reached a high level of maturity. In this article, we focus on five different printing and bronze techniques. The five bronzing techniques are described below. Each of these five methods has unique qualities that make it useful for printing. There is a wide variety of bronzing techniques to select from, making it ideal for use with a wide variety of custom box designs.

What Are 5 Printing And Bronzing Processing Methods?

1. Flat Ironing

The most popular technique for stamping uses a flat iron. The metal will only be present in the sections that need to be ironed; the other sections will be blank or printed. The goal of a flat iron is to gild the most relevant information and draw attention to the bronzing spot. When compared to methods like reverse ironing and repeated ironing, flat ironing is simpler and less prone to error. Further, since this is the most basic stamping method, paper waste will be minimal.

2. Reverse Ironing

Flat ironing’s antithesis is the reverse ironing technique. To emphasize the blank area, a metal hollow-out is employed, and the bronzing serves as a contrast. The regular practice calls for a colossal figure to be drawn around the area of the picture and text that should be emphasized. The effect of anti-ironing is achieved by gilding the surrounding figure and hollowing down the picture or word to be emphasized. The cost of reverse ironing increases with the size of the foil area. In addition, the lines in any graphics or text that are particularly noticeable shouldn’t be too thin (more than 6pt is necessary), since this might distort the final output.

It’s important to think about the peculiarities of paper grain if you’re going to utilize specific paper for bronzing. Reverse bronzing is not advised if the surface is not completely smooth, since the fineness of big area hot stamping is readily influenced by paper grain.

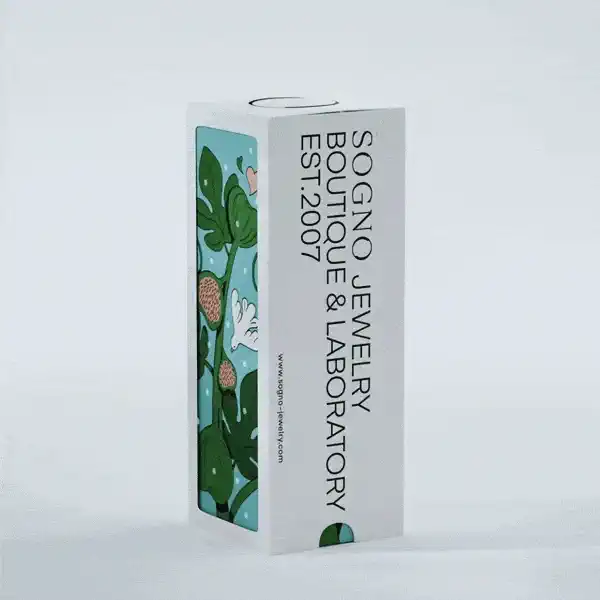

3. Printing And Ironing Overlap

Overlapping printing and ironing are both processing steps that need mastery. The printing technique used expertly combines bronzing with the color printing process. The master printer will begin with the printing process, followed by the bronze finishing. Hot stamping requires precise placement, but the end result is exciting and high-quality. This technique is a test of the master’s expertise as well as the designer’s ability to conceptualize harmonious color combinations.

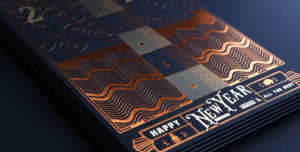

4. Multicolor Gilding

Many designers may stamp the same picture or phrase many times, or in different colors, to draw attention to it. It is comparable to the hot stamping overlap in that it requires a high-precision hot stamping process. Color and bronzing overlap in hot stamping, and multi-color hot stamping refers to the overlap of numerous hot stamping colors. Hot stamping many colors repeatedly requires careful consideration of hot stamping location and gold foil compatibility. When designing, if the designer makes the two bronzing distances too close together, he may mix the colors by simply pasting them together.

5. Stereoscopic Gilding

Three-dimensional bronzing is achieved by combining the bronzing and embossing processes to create a relief appearance that seems to protrude from the surface. Keep in mind that the rear of the unidimensional bronzing will be concave, so while you’re creating, you should avoid putting any artwork or writing there.

Top 10 Creative Cosmetic Packaging Design Ideas & illustrations 2023 | Luxury-Paper-Box.Com

10 Customs Of The Spring Festival (Lunar New Year) You Need To Know

Top 10 Best Lattafa Perfumes for Women & Men in 2024

Top 10 Best Packaging Design Software 2023 (Free & Paid)

Best Chocolate Packaging Designs of 2025

Natural Concept Perfume Design Ideas: Tell Your Brand Story

kali@luxury-paper-box.com

kali@luxury-paper-box.com