What Are The Newest Printing Technology And Materials

The printing technology is only reflected on the surface of the packaging. This is because at this stage, the products sold in the market are diverse. The storage shelves of shopping malls and large shopping malls have already become the “arena” of fierce market competition of well-known brands. Excellent printing technology can make the commercial packaging more and more vivid and quickly attract the attention of customers. Today, we are showing you the 6 newest printing technology and materials for your packaging.

Nanotechnology packaging and printing

In the printing industry, the main performance ability of key points is one of the key specifications to distinguish the quality of printed matter, which is very possible for the potential application of nano materials. In fact, from the drupa2012 exhibition, the “nanotechnology printing process” presented by enterprises is actually the most eye-catching application of new digital printing technology at the exhibition. Nanotechnology printing equipment integrates the characteristics of strong coordination ability of digital printing and high efficiency and rationality of traditional screen printing, which can not only achieve high productivity, but also seamlessly connect with the existing office environment of packaging and printing companies.

Graphene conductive ink

In the electronic city of intelligent packaging and packaging printing, silver paste and copper paste conductive inks have long dominated, but in 2011, graphene conductive inks gradually gained popularity and generated new expectations for the sales market.

Graphene conductive ink has excellent conductivity. In addition, it also has other advantages that silver conductive ink does not have, such as lower price and softer – raw materials can wrinkle or bend without harming properties. Because of its outstanding advantages, graphene conductive ink will become a new force in the sales market of conductive ink.

No water screen printing

No water screen printing is a screen printing process without water or wetting system software. For a long time, the packaging and printing industry has been cautious about packaging and printing without water. However, in the past two years, according to the full cooperation among printing equipment manufacturers, printing paper and printing ink manufacturers, the processing technology of screen printing without water has already achieved great development. No water screen printing, silica gel sizing printing plate, unique printing ink and temperature controlled printing equipment are selected. Without water screen printing, many printing process raw materials can be packaged and printed more easily and efficiently, including printing paper and all kinds of non speed printing process raw materials.

High fidelity audio color control

Luxury box packaging color is the most powerful special marketing tool for retail products. Even if customers are likely not to notice this, it is true. When shopping, customers will generally identify the well-known brand logo of the product first, and then carefully read the indication logo of the product. This reflects the necessity of commodity brand logo color.

Code printing software for thermal inkjet printer

For a long time, in order to complete the product coding software in the production line of their own processing plant, there are mostly three printing technologies: laser coding software, continuous inkjet printer coding software and thermal migration coding software. Now, they have another choice, that is, thermal inkjet printer coding software. In fact, thermal inkjet printer technology has been successfully used in the office industry for many years, but it has not been used in industrial production until recently. Moreover, the technology of thermal inkjet printer continues to improve in the aspects of printing ink, drying rate and the adaptability of raw materials of printing process, and its temptation to packers is also increasing.

Degradable printing ink

With the continuous rise of the call for low-carbon environmental protection, the concept of sustainable development has attracted much attention in the packaging industry, and its necessity has become increasingly prominent. The packaging printing and printing ink sales market, which is separated from the packaging industry, also attaches more importance to the concept of ecological environment protection and sustainable development. Therefore, a new generation of environmental protection printing inks and printing technologies emerge one after another.

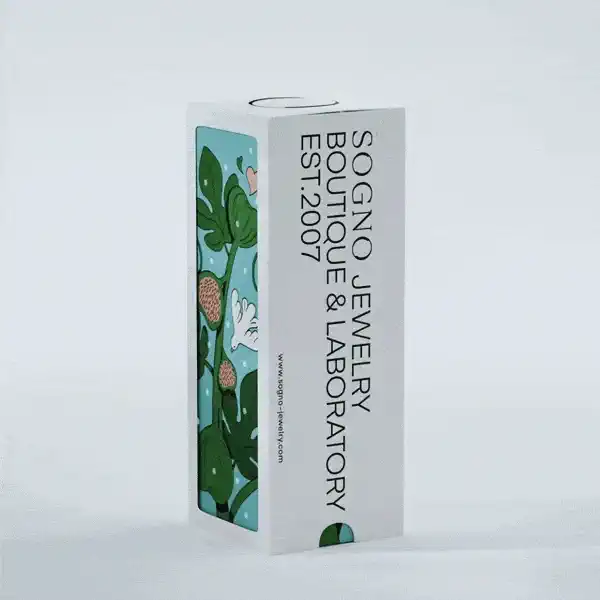

Top 10 Creative Cosmetic Packaging Design Ideas & illustrations 2023 | Luxury-Paper-Box.Com

10 Customs Of The Spring Festival (Lunar New Year) You Need To Know

Top 10 Best Lattafa Perfumes for Women & Men in 2024

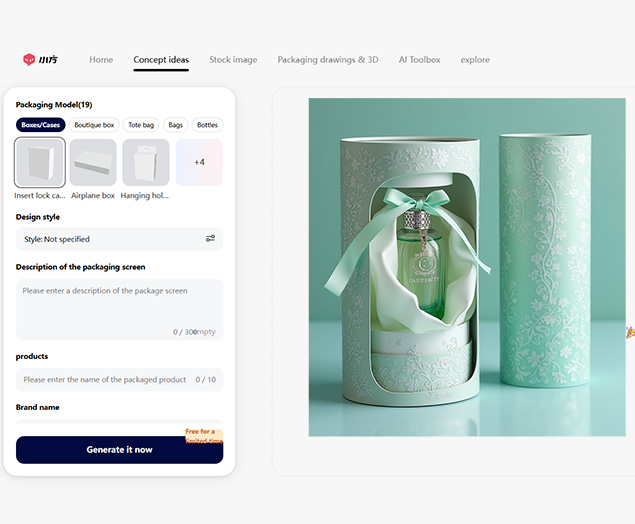

Top 10 Best Packaging Design Software 2023 (Free & Paid)

Best Chocolate Packaging Designs of 2025

Natural Concept Perfume Design Ideas: Tell Your Brand Story

kali@luxury-paper-box.com

kali@luxury-paper-box.com