Which Printing Method Is Most Effective On Packaging, Particularly Food Packaging?

In the modern era of consumerism, custom packaging plays a vital role in attracting and engaging customers. It serves as a powerful marketing tool, communicating brand identity and product information. When it comes to food packaging, various printing methods are available, each with its own set of advantages and limitations. This article aims to delve into the different printing methods used in food packaging, analyze their effectiveness, and help determine the most suitable approach for various requirements.

Comparing Printing Methods for Packaging: Determining the Most Effective Approach

In the modern era of consumerism, packaging plays a vital role in attracting and engaging customers. It serves as a powerful marketing tool, communicating brand identity and product information. When it comes to food packaging, various printing methods are available, each with its own set of advantages and limitations. This article aims to delve into the different printing methods used in food packaging, analyze their effectiveness, and help determine the most suitable approach for various requirements.

- 1. Offset Printing

Offset printing is a popular and versatile technique that involves transferring ink from a plate to a rubber blanket before applying it to the printing surface.

1.1 Process and Technology

Offset printing uses a series of rollers and cylinders to transfer ink to the substrate. It offers precise color reproduction and excellent detail.

1.2 Advantages and Limitations

Offset printing provides high-quality prints, supports a wide range of substrates, and is cost-effective for large production runs. However, it requires longer setup times and is less suitable for short runs or frequent design changes.

1.3 Application in Food Packaging

Offset printing is commonly used for various food packaging applications, including cartons, labels, and folding cartons.

1.4 Effectiveness Evaluation

Offset printing is effective in delivering vibrant colors, sharp images, and intricate details on food packaging. Its high print quality makes it suitable for premium products, but its setup time and cost may not be ideal for short runs or specialized designs.

- 2. Flexographic Printing

Flexographic printing, also known as flexo printing, utilizes flexible relief plates and quick-drying inks to transfer the design onto various substrates.

2.1 Process and Technology

Flexo printing uses a rotating cylinder with raised image areas that transfer ink to the substrate. It is commonly used for high-speed production.

2.2 Advantages and Limitations

Flexographic printing offers fast production speeds, excellent ink coverage, and good cost efficiency for medium to large runs. However, it may have limitations in achieving fine details and color accuracy.

2.3 Application in Food Packaging

Flexo printing is widely employed in food packaging, including flexible packaging, labels, and corrugated boxes.

2.4 Effectiveness Evaluation

Flexo printing provides good print quality, vibrant colors, and strong ink adhesion for food packaging. Its efficiency and cost-effectiveness make it suitable for large production volumes, but it may not deliver the same level of detail as offset printing.

- Digital Printing

Digital printing is a versatile method that utilizes advanced technologies to directly print digital files onto packaging materials, eliminating the need for plates or cylinders.

3.1 Process and Technology

Digital printing involves transferring ink or toner onto the substrate using inkjet or electrophotographic processes. It offers quick setup times and the ability to customize each print.

3.2 Advantages and Limitations

Digital printing provides fast turnaround times, variable data printing capabilities, and reduced waste. However, it may have limitations in color gamut and may be less cost-effective for very large production runs.

3.3 Application in Food Packaging

Digital printing is well-suited for short to medium runs and on-demand printing of food packaging, such as labels, wrappers, and pouches.

3.4 Effectiveness Evaluation

Digital printing allows for high-quality prints, sharp images, and the ability to customize each package. It offers flexibility for personalized packaging and shorter runs, making it ideal for niche products or limited editions. However, it may have limitations in achieving certain special effects and cost efficiency for large-scale production.

- 4. Gravure Printing

Gravure printing, also known as intaglio printing, employs engraved cylinders to transfer ink onto the packaging material, creating high-quality and consistent prints.

4.1 Process and Technology

Gravure printing uses recessed cells on a cylinder that pick up ink and transfer it to the substrate. It is known for its ability to reproduce fine details and intricate designs.

4.2 Advantages and Limitations

Gravure printing offers excellent print quality, precise color reproduction, and the ability to print on a variety of substrates. However, it is more suitable for long runs due to setup costs and may have limitations in flexibility and quick turnarounds.

4.3 Application in Food Packaging

Gravure printing is commonly used for high-quality food packaging, including flexible packaging, labels, and shrink sleeves.

4.4 Effectiveness Evaluation

Gravure printing excels in delivering consistent and high-resolution prints with vibrant colors and intricate details. It is often chosen for premium food products, but its setup costs and longer lead times may not be suitable for shorter runs or frequent design changes.

- 5. Screen Printing

Screen printing, also known as silkscreen printing, involves forcing ink through a fine mesh stencil onto the substrate, resulting in vibrant and opaque prints.

5.1 Process and Technology

Screen printing uses a mesh screen with open areas that allow ink to pass through onto the packaging material. It is a versatile printing method suitable for various substrates.

5.2 Advantages and Limitations

Screen printing offers excellent ink coverage, durability, and the ability to print on different surfaces. However, it may have limitations in achieving fine details and is more time-consuming for multi-color designs.

5.3 Application in Food Packaging

Screen printing is commonly used for food packaging, such as glass bottles, plastic containers, and promotional items.

5.4 Effectiveness Evaluation

Screen printing delivers vibrant and opaque prints with good adhesion on food packaging. It is suitable for designs that require solid colors and strong visual impact, but it may not be the most efficient method for intricate designs or large production runs.

Comparison and Evaluation

Print Quality and Color Reproduction – In terms of print quality and color reproduction, offset printing, gravure printing, and digital printing offer excellent results with sharp details and vibrant colors. Flexographic printing and screen printing can also achieve good print quality, but they may have limitations in reproducing fine details and subtle color gradients.

- Cost Considerations – Offset printing and flexographic printing are cost-effective for medium to large production runs, thanks to their efficient setups and economies of scale. Digital printing offers cost advantages for shorter runs and on-demand printing, eliminating the need for plates. Gravure printing and screen printing may have higher upfront costs due to cylinder or screen preparation.

- Production Speed and Efficiency – Flexographic printing, gravure printing, and screen printing are known for their high-speed production capabilities, making them suitable for large volumes. Digital printing offers quick setup times and on-the-fly customization, making it efficient for short runs and personalized packaging. Offset printing may have longer setup times but can achieve high-speed production once set up.

- Sustainability and Environmental Impact – Digital printing stands out as an environmentally friendly option due to its reduced waste and the absence of plates or cylinders. Offset printing and flexographic printing have made strides in adopting eco-friendly practices. Gravure printing and screen printing may have more significant environmental impact due to the use of solvents and longer cleanup processes.

- Compatibility with Different Packaging Materials – Offset printing, flexographic printing, and digital printing can be used on various packaging materials, including paper, cardboard, and certain plastics. Gravure printing excels in printing on flexible films and foils, while screen printing offers versatility in printing on diverse surfaces such as glass, metal, and plastic.

- Regulatory Compliance and Food Safety – All printing methods can meet regulatory requirements for food packaging, provided that proper inks and materials are used. It is essential to ensure compliance with food contact regulations and consider factors such as migration, odor, and overall safety.

- Overall Effectiveness Evaluation – Considering the various factors discussed, there is no one-size-fits-all approach to determining the most effective printing method for food packaging. Each method has its strengths and limitations, and the choice depends on specific requirements, such as print quality, cost considerations, production speed, sustainability goals, packaging material compatibility, and regulatory compliance. For high-quality prints and large-scale production, offset printing and flexographic printing are suitable options. Digital printing offers flexibility and cost advantages for shorter runs and customization. Gravure printing and screen printing excel in certain applications that require fine details or printing on unique surfaces.

After a comprehensive analysis of various printing methods used in food packaging, it is evident that each method has its own unique strengths and limitations. The choice of printing method ultimately depends on several factors, including the desired print quality, cost considerations, production speed, sustainability goals, packaging material compatibility, and regulatory compliance. It is crucial for packaging manufacturers and brand owners to carefully evaluate these factors and select the most effective printing method that aligns with their specific requirements and objectives. By making an informed decision, they can enhance the visual appeal of their food packaging, improve brand recognition, and foster consumer trust and loyalty in an increasingly competitive market landscape.

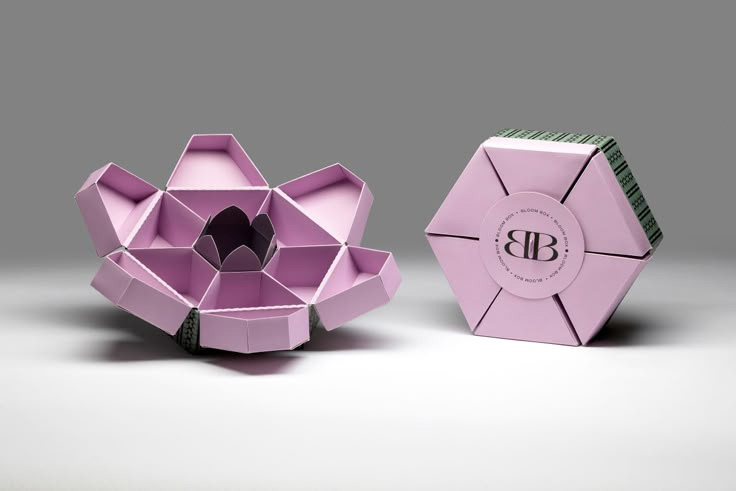

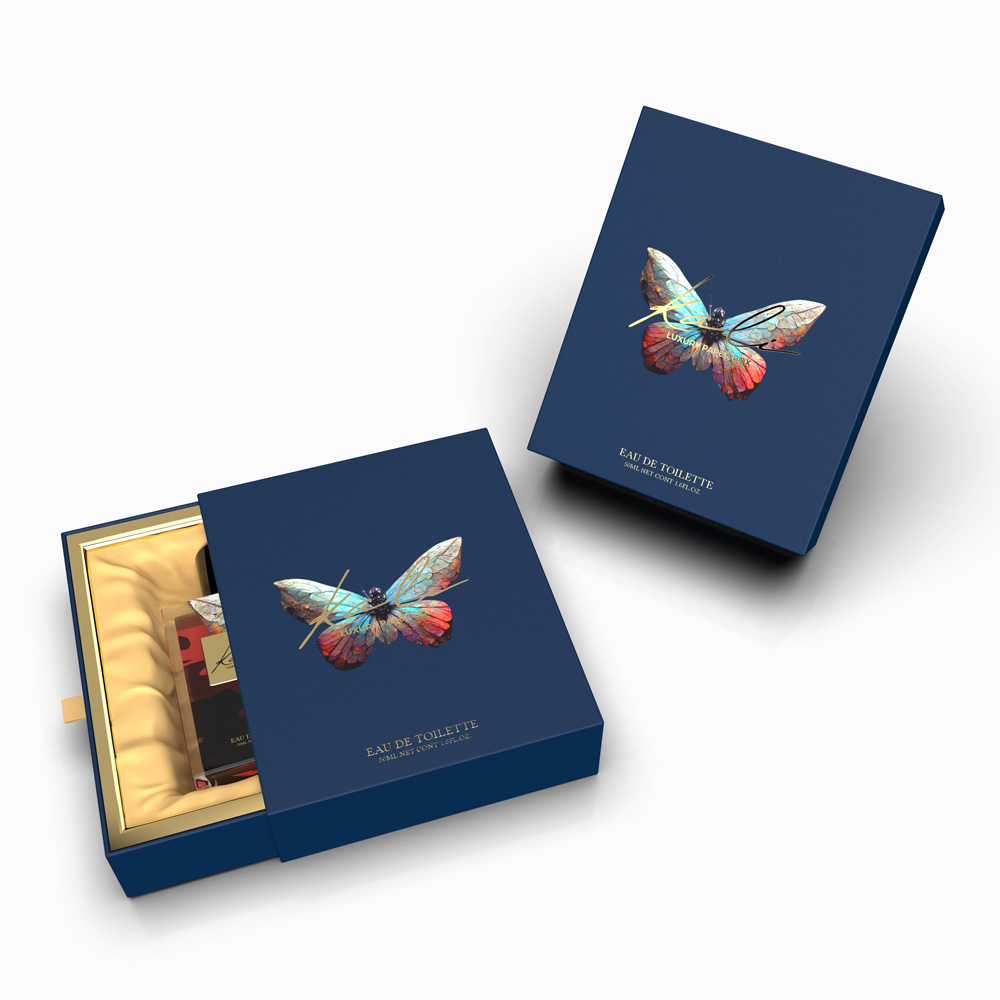

Top 10 Creative Cosmetic Packaging Design Ideas & illustrations 2023 | Luxury-Paper-Box.Com

10 Customs Of The Spring Festival (Lunar New Year) You Need To Know

Top 10 Best Lattafa Perfumes for Women & Men in 2024

kali@luxury-paper-box.com

kali@luxury-paper-box.com